Max. Processing Size: 6000*2500mm

Max. Speed: 120m/min

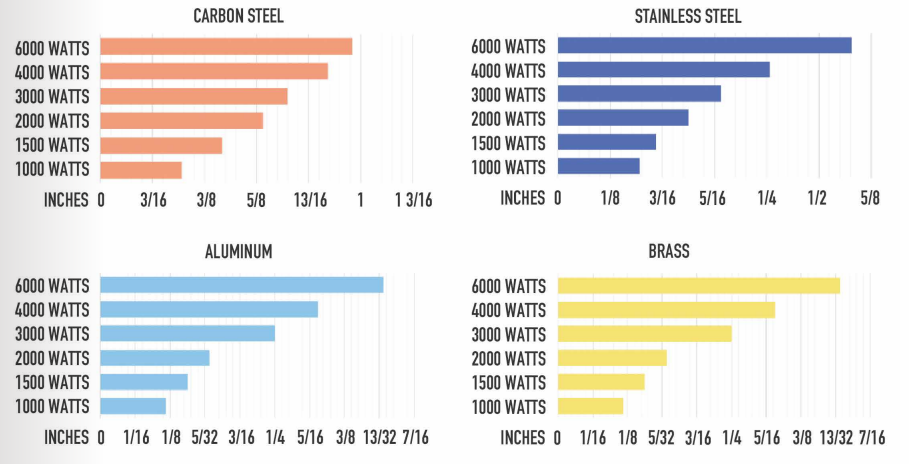

Laser Power: 1500-60000W

Tubesheet Fiber Laser Cutter is an advanced cutting equipment that combines fiber laser technology and CNC numerical control technology, specifically designed for efficient and high-precision cutting of metal tubes and sheets. This device can not only meet the cutting needs of flat plates, but also handle the cutting of various types of tubes such as round tubes, square tubes, and special-shaped tubes.

| Model | HM3015DT | HM4015DT | HM4020DT | HM6020DT | HM6025DT |

| Processing Size | 3000*1500mm | 4000*1500mm | 4000*2000mm | 6000*2000mm | 6000*2500mm |

| Dia. Of Machinable Tube | ≤6000mm*φ20mm-φ200mm (Chuck 160/220/350/500 Customized) | ||||

| X/Y axis Positioning Accuracy | ±0.05mm | ||||

| Max. Speed | 120m/min | ||||

| Max. Acceleration | 1.5G | ||||

| Max. Rotating speed | 80r/min | ||||

| Min. Kerf | ≥0.15mm | ||||

| Laser Power | 1500-60000W | ||||

INDUSTRIES

|  |  |  |

| Fitness Equipment | Engineering Machinery | Boiler Manufacturing | Elevator Manufacturing |

|  |  |  |

| Chemical Equipment | Furniture Manufacturing | Bathroom Hardware | Instruments |

MATERIALS

|  |  |  |

|  |  |  |

Advantages of Tubesheet Fiber Laser Cutter:

1. High precision: Adopting

imported high-precision reducers, servo motors, dual drive racks, gears

and other transmission systems to ensure the quality and dimensional

accuracy of cutting edges; High energy density laser beams can achieve

micrometer level cutting accuracy, ensuring smooth and deformation free

cutting edges.

2. High efficiency: The front and

rear adopt pneumatic chuck clamping design, automatically adjust the

center, and the diagonal adjustment range is 20-300mm; Automatic

centering, no need to adjust claws, good stability, fast pipe cutting

speed; Capable of processing ultra large diameter pipes, with high chuck

rotation speed, better accuracy, and high cost-effectiveness.

|  |  |  |

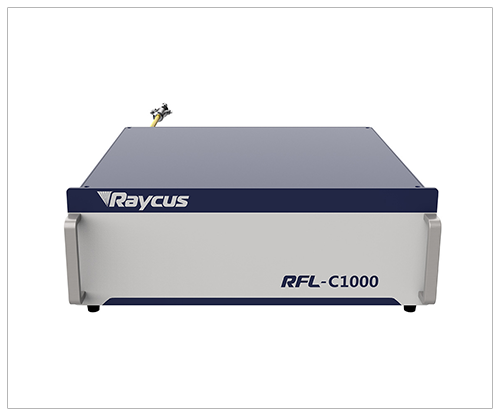

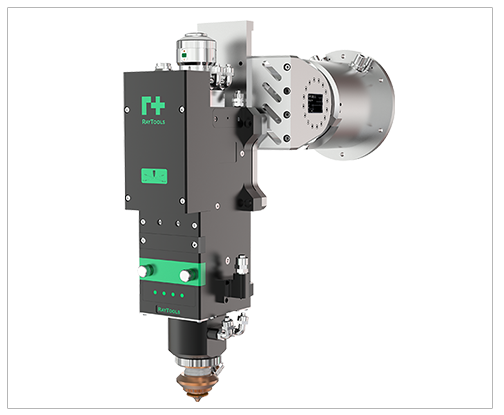

| Raycus Laser | Raytools laser cutting head | Motovario Reducer | Mitsubishi Servo Motor |

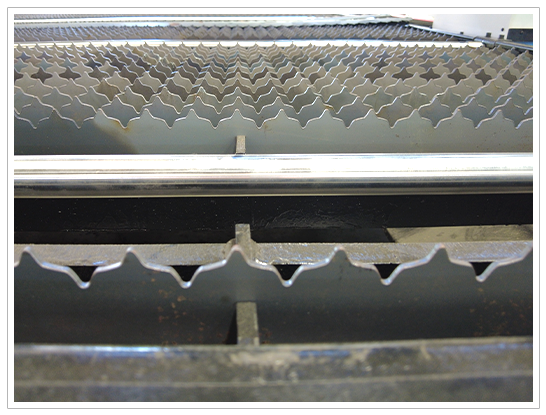

3. Good cutting quality: The incision is flat and smooth, requiring no further processing or only a small amount of treatment.

4. Good stability:

using top-class fiber lasers, compact structure, low energy

consumption, stable and reliable cutting quality; The overall design of

the equipment is reasonable, with stable movement, ensuring long-term

high-precision operation. The application of stress relief annealing

technology has high mechanical strength, eliminates residual stress on

the bed, ensures long-term stability of the machine tool, and ensures

that the bed is not easily deformed for many years.

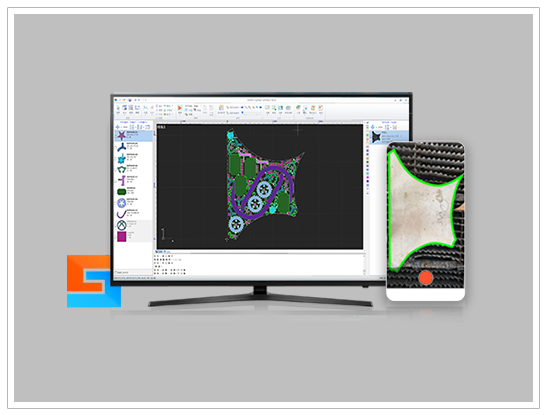

5. High degree of intelligence:

adopting professional and advanced 3D nesting software and CNC cutting

software, with high-speed data processing and real-time control

functions, it can automatically recognize the characteristics of

different tube sheet materials and make corresponding cutting settings,

and can freely design various graphics or text, with flexible

processing, simple and convenient operation; Equipped with visual

collision protection, seamless perforation, automatic obstacle

avoidance, flight cutting, intelligent coding and other functions.

|  |  | |

| Nesting Software | Chuck | Bed Structure | Safety Grating |

6. Low cost:

There is no need for tool wear during the laser cutting process,

reducing the cost of consumables; The laser beam energy is concentrated,

the heat affected zone is small, and the workload of subsequent

processing is reduced; Fiber laser has high photoelectric conversion

efficiency and low energy consumption; Long service life and relatively

simple maintenance; One machine for cutting pipes and plates is

versatile, meeting diverse processing needs and reducing equipment

investment and maintenance costs; Laser cutting speed is fast, greatly

shortening the processing cycle; High degree of automation, reducing

labor costs; By optimizing the layout, materials can be effectively

utilized and waste can be reduced.

7. Environmental friendly:

Laser cutting technology does not require contact with the surface of

the workpiece, reducing waste generation and environmental pollution;

There is no noise or pollution during the cutting process.

Pre sales service

Based on user needs, provide practical technical advice and corresponding product information from the user's perspective to answer and solve various questions raised by users. From a technical feasibility perspective, assist users in developing processing plans, provide processing equipment for on-site visits and inspections, sampling and testing, etc.

|  |  |  |  |

In sales service

Provide users with a complete set of product operation manuals for their processing sites, conduct on-site inspections, assist users in planning and designing production sites, as well as equipping water, electricity, and gas according to the actual situation on site, and provide technical training for user operators.

After-sale service

The equipment arrives at the user's installation and commissioning site, and further training is provided to the user's operators, which is synchronized with installation and commissioning to ensure that the operators are proficient in the equipment operating procedures and fully put into production. Our company will send engineering and technical personnel to the user site irregularly every year for technical patrols, routine maintenance and inspection of equipment, answering technical questions raised by users, and providing upgrade training for user operators.

|  |

|

|  |

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.