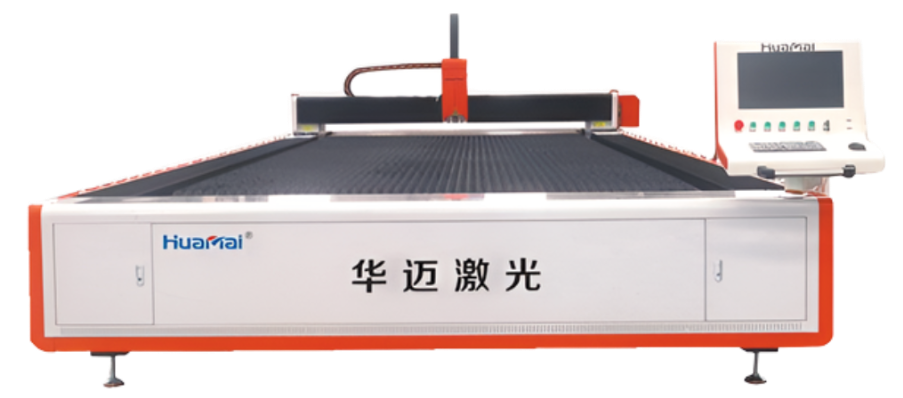

Metal materials are important products in the manufacturing industry. To fully utilize this material, it must be cut and formed using equipment, and laser cutting machines are important mechanical equipment in the metal forming industry. Compared to other types of cutting machines, laser cutting machines have a high degree of automation, a wider range of applications, higher cutting efficiency and accuracy, and are therefore widely popular in the manufacturing industry.

As a sharp tool for metal cutting, laser cutting machines need to master their working principles and operating procedures in order to fully utilize their work efficiency. Today, we will learn how to operate a laser cutting machine together.

It is not difficult to understand the working principle of the metal laser cutting machine. The laser cutting machine uses the focused laser beam with high power and high energy density to illuminate the workpiece, so that the irradiated material can quickly melt, vaporize, ablate or reach the ignition point. At the same time, it uses the high-pressure Jet stream air flow coaxial with the beam to blow off the molten material, thus cutting the workpiece.

To operate a metal laser cutting machine, it is usually necessary to follow the following steps:

1. Turn on the working circuits of each part, including the main power switch, voltage regulator, fiber laser power switch, air compressor, air circuit valve, cold dryer, etc., to ensure that the power supply system of each part is normal;

2. Test run the machine and confirm that it runs smoothly, and that all limits and emergency buttons are secure;

3. Place the material to be cut smoothly on the cutting table of the machine tool, operate the console computer screen, input parameters such as product material thickness, and import the pattern into the machine;

4. Control the movement of each axis through the functions in the menu, and adjust the cutting position to the appropriate part of the board;

5. Select suitable nozzles and lenses, and conduct inspections to ensure that their appearance and cleanliness are in good condition; Adjust the cutting head to the appropriate cutting focus position through the direction keys on the panel;

6. Select suitable cutting gases based on cutting needs and check if their spraying status is good;

7. Start the laser and machine tool, test cut the metal raw materials, observe whether the cross-section is smooth and the cutting accuracy is accurate. If there is any deviation, adjust the equipment parameters until the sample meets the requirements; Then the device automatically starts cutting according to the input parameters and patterns;

8.During the cutting process, there must be staff present. If there is an emergency that requires quick response, the staff must quickly press the brake button;

9. After completing the cutting work, pay attention to checking the cutting accuracy and quality of the product;

n addition, after using the fiber laser cutting machine, it is necessary to shut down the machine to reduce fiber laser faults and increase the machine's service life. The specific operations are as follows:

(1) Turn off the laser.

(2) Turn off the chiller.

(3) Turn off the gas and vent the gas from the pipeline.

(4) Raise the Z-axis to a safe height, turn off the CNC system, and seal the nozzle with transparent adhesive to prevent dust from contaminating the lens.

(5) Clean the site and record the operation of the cutting machine on that day. If there is a malfunction, it should be recorded in a timely manner for maintenance personnel to diagnose and repair.

(6) When the laser cutting machine is idle, the staff should ensure that the equipment is clean, regularly clean each guide rail, wipe the equipment rack, and apply lubricating oil.

It is worth noting that when operating a metal laser cutting machine, in addition to strictly following the operating procedures, personal protection should also be taken. For example, when near the laser beam, protective glasses that meet the requirements should be worn to avoid unnecessary risks. If you are a novice operator, you must refer to all relevant manuals or receive professional training before taking up your job. Do not use or operate arbitrarily.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.