How should we choose low, medium, and high power fiber laser cutting machines? People familiar with the fiber laser cutting machine industry know that different power fiber laser cutting machines have different cutting capabilities and cutting thickness ranges. Customers have different requirements for the configuration of fiber laser cutting machines due to the different materials they want to cut. Therefore, the market has a demand for low, medium, and high power cutting machines. So, when choosing a suitable fiber laser cutting machine, how to choose its power?

The material cut by the fiber laser cutting machine is metal, mainly including stainless steel, carbon steel, aluminum plate, brass, etc. Generally speaking, the higher the equipment power, the thicker the cutting thickness. The power size mainly depends on the laser. In the market, 2000W and above are generally referred to as high power, power between 1000W and 2000W is medium power, and power below 1000W is called low power. From the current demand, the market has a high demand for 2000W fiber laser cutting machines, which can meet most cutting needs. Cutting speeds above 2000W may be faster, but at the same time, prices are also higher. The power level is one of the main factors that directly affect the price of laser cutting machines.

For thinner stainless steel and carbon steel plates, it is possible to use a low-power fiber laser cutting machine to cut very well, while also ensuring a high cutting speed, which not only ensures work efficiency but also saves costs.

Therefore, when choosing a laser cutting machine, it is necessary to make a reasonable choice based on one's own material and material thickness, and not blindly pursue high power.

Of course, if you have both thick and thin plates for processing, and the production capacity demand is very high, a high-power laser cutting machine within the price range that you can afford is also a better choice. Because by adjusting the cutting speed appropriately and replacing auxiliary gases, high-power laser cutting machines can also control the cutting quality of thinner plates very well.

So customers should consider two things when purchasing fiber laser cutting machines. Firstly, meet the cutting requirements of customers; Secondly, the price is within one's own affordability range. The power of a laser cutting machine is one of the important factors that you need to consider, but it does not necessarily mean blindly pursuing high power.

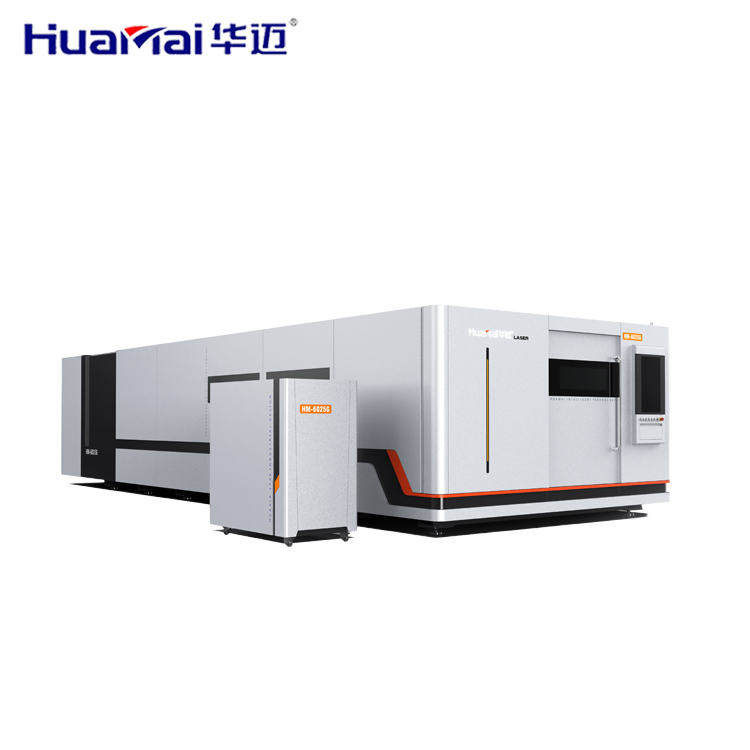

Diversified products to meet the diverse needs of different users for fiber laser cutting machines. Customers in the hardware and kitchen and bathroom industries are mainly suitable for small fiber laser cutting machines; Customers in the advertising, sheet metal, and chassis industries generally choose high-power fiber laser cutting machines; Customers in industries such as aviation, aerospace, rail transit, and automobiles must choose high-power fiber laser cutting machines. Overall, the choice of a high-power fiber laser cutting machine depends on the customer's cutting needs.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.