Max. Processing Size: 26000*3500mm

Max. Speed: 150m/min

Laser Power: 3000-60000W

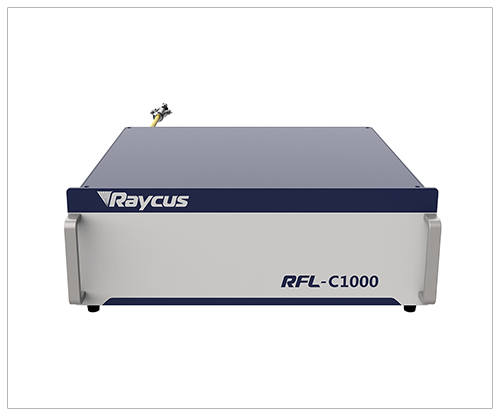

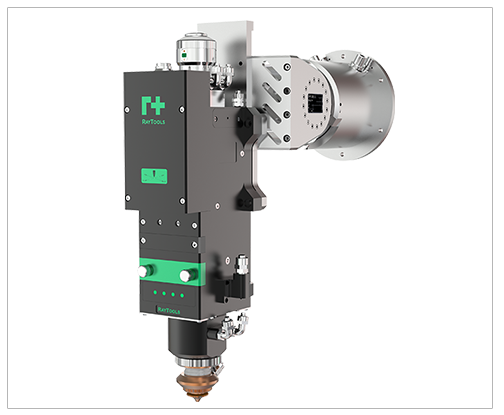

Plate Laser Cutter is usually composed of fiber laser, cutting head, high-power laser power supply, water-cooled cabinet, and computer operation desk. They can efficiently and accurately complete the straight cutting and bevel cutting of large format metal sheets, and can achieve multi angle bevel cutting, such as ±45° bevel cutting. They can cut various bevel shapes such as V, K, X, Y, etc., to meet different welding and processing needs.

Model | HM3015D | HM4020D | HM6025D | HM8025D | HM13031D |

Processing Size | 3000*1500mm | 4000*2000mm | 6000*2500mm | 8000*2500mm | 13000*3100mm |

X/Y axis Positioning Accuracy | ±0.04mm | ||||

Repositioning Accuracy | ±0.05mm | ||||

Min. Kerf | ≥0.15mm | ||||

Max. Speed | 120m/min | ||||

Max. Acceleration | 1-2.5G | ||||

Laser Power | 3000-60000W | ||||

Product Description

Product Details

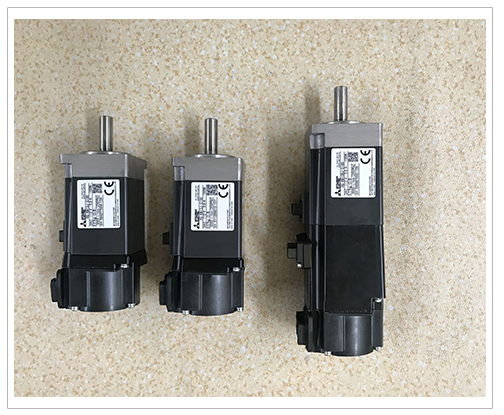

usually reach about 0.1mm. Servo motors, reducers, and dual drive gear rack transmission structures are sourced from famous brands to ensure precision and processing efficiency requirements during the cutting process.

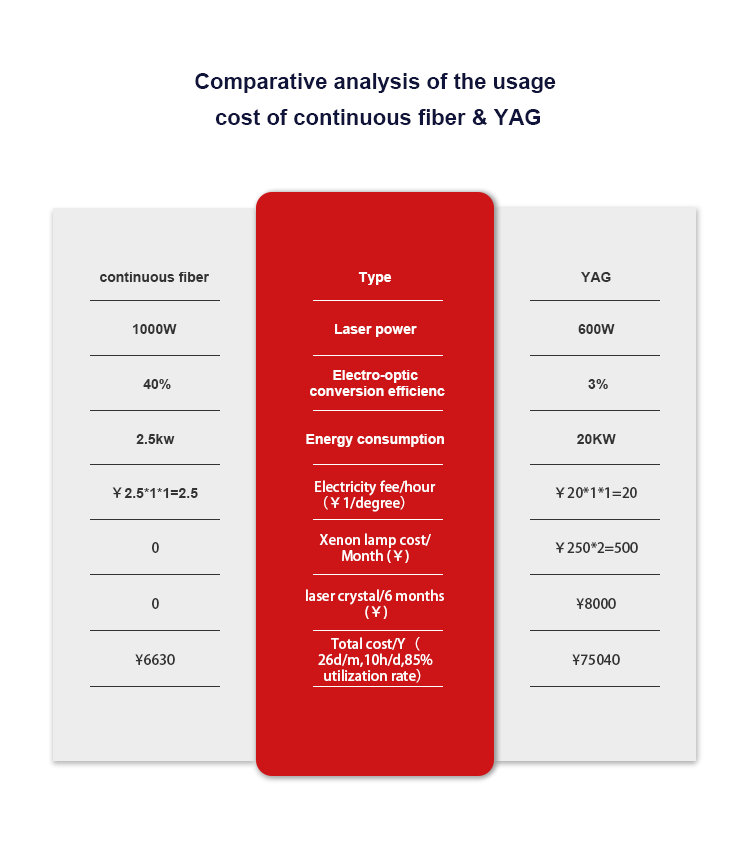

2. High efficiency: Using fiber optic transmission of laser beams, the laser transmission loss is small, the energy conversion efficiency is high, and the cutting speed and efficiency are effectively improved. Compared to traditional cutting methods, the cutting speed of high-speed fiber laser cutting machines can be increased several times, suitable for large-scale production, and shorten the production cycle.

|  |  |  |

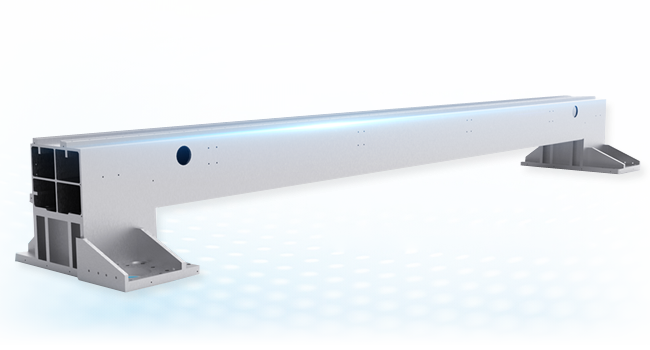

| Laser | Laser cutting head | Reducer | T6 grade crossbeam |

|  |  | |

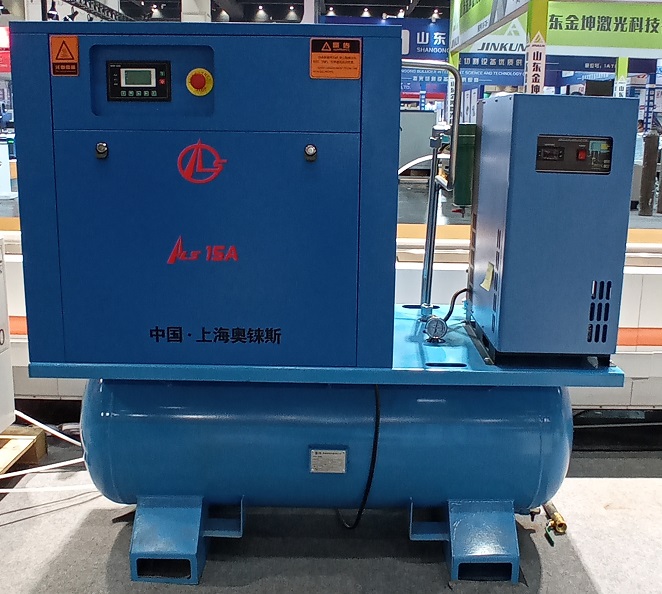

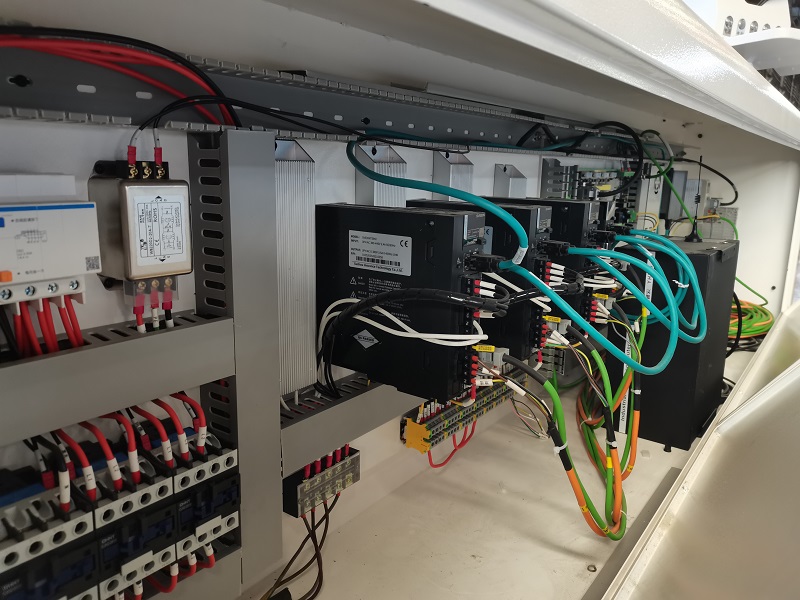

| Servo motor | Air compressor | Electric control cabinet | Linear guide |

3. Good stability: Fiber lasers have a long service life and excellent stability, ensuring stable and reliable cutting quality. Adopting a gantry crossbeam design, high-strength aerospace grade integrated cast aluminum alloy. Adopting a fully enclosed dust-proof structure greatly improves the service life of the gears, racks, and linear guides installed inside.

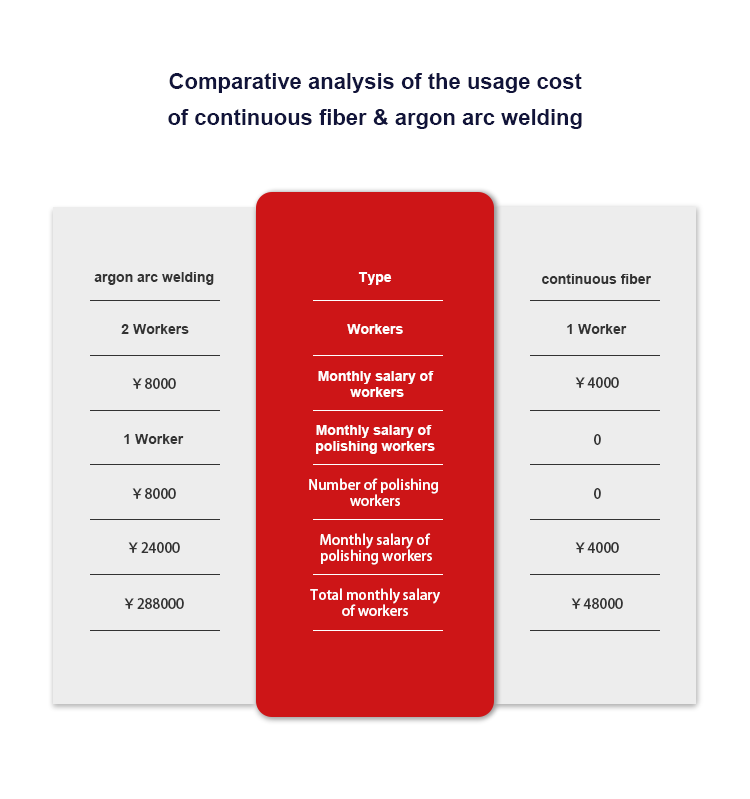

4. Low operating cost: Compared to traditional cutting methods, fiber laser cutting machines do not require frequent replacement of cutting tools and consumables. High precision cutting reduces material waste and the need for secondary processing, improves material utilization, and reduces production costs. At the same time, lower maintenance costs and energy consumption further reduce overall operating costs.

5. Environmentally friendly: Using lasers as cutting tools, there is no need to use cutting fluids or other chemical agents, avoiding environmental pollution. Segmented smoke exhaust, the bed has a smoke exhaust port, and automatic smoke exhaust is carried out through the smoke exhaust pipe, which can easily discharge the smoke and dust generated during the cutting process outdoors, improving the working environment.

6. Intelligence: Mature and professional operating system, user-friendly interface, real-time feedback on processing status, ensuring orderly cutting and processing, simple and intuitive operation; Operators only need basic training to get started with the operation. The digital control system can automate the generation and adjustment of cutting trajectories, achieving efficient and accurate cutting, reducing operational difficulty and error rates. Non sensory perforation, empty movement obstacle avoidance, visual residual material cutting

Sample Display

Application Scenarios

After-sale service

How to choose a suitable Fiber Laser Pipe Cutting Machine?

1. Confirm cutting requirements: Determine the size (diameter, wall thickness, length, etc.) and material (such as stainless steel, carbon steel, aluminum alloy, etc.) of the pipe to be cut, as well as the cutting process to be performed (such as cutting, drilling, oblique cutting, intersecting line cutting, etc.). At the same time, possible changes in processing demands in the future should also be considered.

2. Match processing capability: According to the diameter of the pipe, it can be divided into large (chuck above 220), medium (chuck between 120-220), and small (for pipes below 60mm) laser cutting machines. According to the degree of automation, there are types such as fully automatic, semi-automatic, and manual feeding. Choose the appropriate laser cutting capability and automation level based on daily processing volume.

3. Determine cutting gas: Understand the cutting gases applicable to the equipment (such as air, nitrogen, oxygen, etc.), as well as the requirements for gas purity (such as nitrogen purity reaching 99.999%), to ensure the provision of suitable cutting auxiliary gases.

4. Equipment quality: Pay attention to product configuration, such as the quality and performance of core components such as fiber lasers (such as German IPG lasers), control systems, cutting heads, etc.

5. Price: Do not simply pursue low prices to avoid falling into the trap of poor quality, but also choose cost-effective equipment based on your own budget, considering the balance between equipment performance, configuration, and price.

6. On site inspection and sampling: If possible, you can go to the manufacturer for on-site inspection to understand their production scale and actual situation. Before purchasing, it is best to have the manufacturer make a sample to observe whether the cutting effect meets the requirements, including cutting accuracy, cutting surface quality, and the presence of burrs.

7. After sales service: Understand the manufacturer's after-sales service capabilities, including response time, problem-solving efficiency, etc. Good after-sales service can solve problems in a timely manner during equipment use and reduce losses.

Certificate

Pre sales service

Based on user needs, provide practical technical advice and corresponding product information from the user's perspective to answer and solve various questions raised by users. From a technical feasibility perspective, assist users in developing processing plans, provide processing equipment for on-site visits and inspections, sampling and testing, etc.

Packaging And Phipping

Exhibition

Huamai Company always adheres to the business philosophy of "building a brand through quality and winning the market through brand". Continuously innovating and developing, committed to creating a world brand of national intelligent equipment, the company has participated in various exhibitions and received enthusiastic responses from market customers.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.