In the welding equipment, in addition to the laser welding machine that everyone is familiar with at present, there is another welding equipment, that is, the cold welding machine. Cold welding machines, internationally known as ESD, use the high thermal energy generated by micro electric instantaneous discharge to melt specialized welding wires onto the damaged parts of the workpiece, firmly fusing with the original substrate, and only requiring minimal polishing and post-processing after welding. What is the difference between cold welding machine and laser welding machine?

1. Differences in principle:

The principle of a multifunctional cold welding machine is to use a charging capacitor to discharge at a cycle of 10-3-10-1 seconds and an ultra short time of 10-6-10-5 seconds. The contact area between the electrode material and the workpiece will be instantly heated to 8000 ° C to 10000 ° C, and the molten metal in the plasma state will transition to the surface of the workpiece through metallurgy. Cold welding machines mainly deposit, seal, and repair defects such as wear, scratches, pinholes, cracks, defects and deformations, hardness reduction, sand holes, and damages on the surface of metal workpieces.

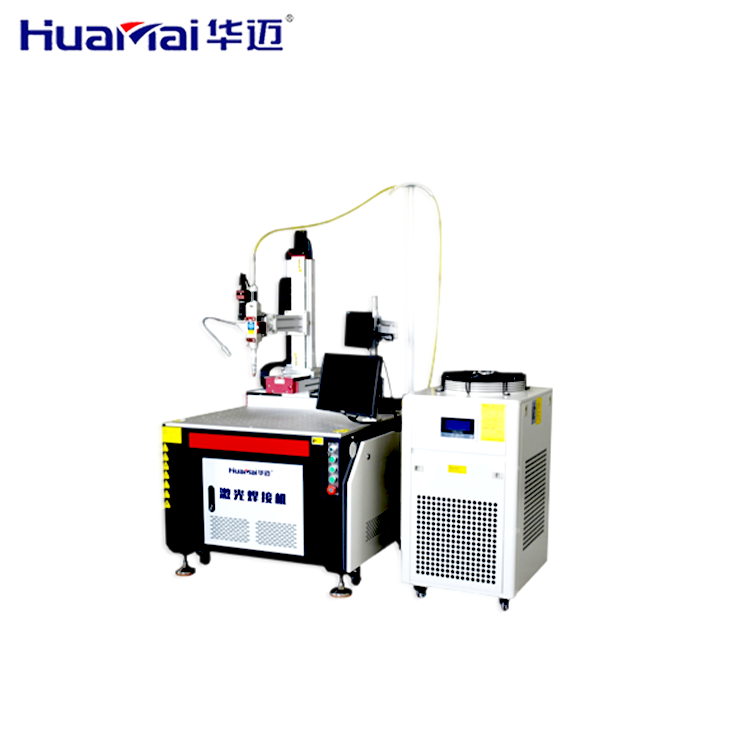

Laser welding machine is to use high-energy laser pulse to locally heat the material in a small area. The energy radiated by the laser diffuses through the inside of the heat conduction guide material, and forms a specific molten pool after melting the material to achieve the purpose of welding. According to its working mode, it can be divided into laser mold welding machine, automatic laser welding machine, laser spot welding machine, and optical fiber transmission laser welding machine.

2. Differences between application functions:

Cold welding machines mainly deposit, seal, and repair defects such as wear, scratches, pinholes, cracks, defects and deformations, hardness reduction, sand holes, and damages on the surface of metal workpieces.

Laser welding machine

The laser welding machine is mainly used for welding thin-walled materials and precision parts, which can realize spot welding, butt welding, overlap welding, seal welding, etc. After welding, the matrix will not be deformed, annealed, undercut and residual stress, and will not change its metal structure state. The repair precision is high. The coating thickness is from several microns to several millimeters, and only needs polishing.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.